Hy-Flex Press NC2 Series

Enables high-precision and high value-added forming. The unitized straightside construction eliminates frame deflection and these presses are equipped with a forced circulation lubrication system.

Ultimate Precision Forming Press UL Series

Provides superior performance for forming applications such as high-precision ironing, squeezing, and bulging applications that require high accuracy and are also affected by forming speeds.

Heavy Stamping Press S1-E Series

The S1-E Series overcomes three limitations related to the forming of thick materials--short die life, vibration and noise--and delivers high precision & high productivity.

Direct Servo Formers DSF-P Series

Reduces the time spent outside of the actual forming window. A system with advanced functionality that enables the pursuit of production optimization to its very limits. Models range in capacity from 4000 kN to 12000 kN.

Progmax Press PMX Series

Link motion improves productivity and assures stable high-precision forming.

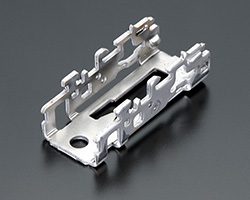

Cold Forging Transfer Press CFT Series

The two-point straightside frame delivers high rigidity and the ability to withstand high off-center loading, thereby expanding the die process design possibilities.

Cold Forging Press FMX Series

Expanding high-performance multi-stage cold forming with a 2-point link motion design and long slide guides.