These are links for moving within this page

- Text Size

-

- Standard

- Large

These are links for moving within this page

It is the main content from here.

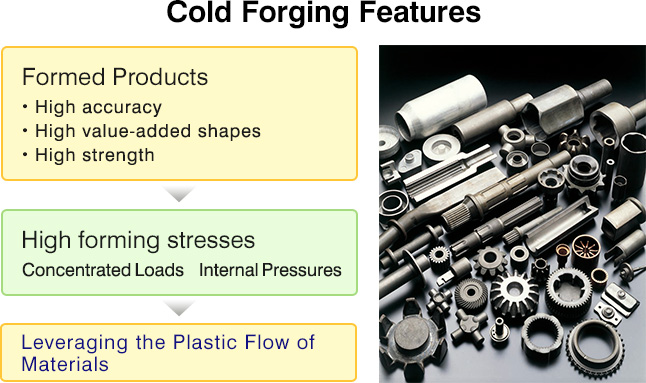

Forging is a forming methodology where compressive stresses are applied to metal material to cause it to flow and deform in order to achieve the required shape.

Forming temperatures can vary greatly--from room temperature to temperatures exceeding 1000°C--but forging processes performed at room temperature (i.e., the material is not heated) are referred to as 'cold forging' processes.

The advantages of cold forging include

1) the forming of high-precision, high value-added products;

2) the conservation of resources and energy; and

3) increased material strength through work hardening

; and cold forging is contributing to production in a wide range of fields, including the electrical appliance and automotive industries.